Legend Robert Mudge

Inventor | 2015 INDUCTEE

Rob Mudge was born in Hot Springs, South Dakota, in 1954. He moved around a bit with his family and finally settled in Rapid City when he was 10 years old. He finished high school there in 1972 and went to college at South Dakota School of Mines & Technology in Rapid City to learn about making and fixing metals. He earned degrees in Metallurgical Engineering. After graduating, Robert worked in the Metallurgical Engineering industry for three years, traveling all over the United States.

Rob really liked Rapid City, so in 1982, he returned to the area and founded RPM & Associates, Inc. with his wife, Debbie, and his parents. The name RPM stands for Robert P. Mudge, and the "Associates" are Debbie and his parents.

RPM & Associates, Inc. helps businesses—such as mines and power plants—by repairing and manufacturing machine parts that wear out over time.

As the company grew, Rob and his team launched two additional businesses:

RPM Solutions, which focuses on pollution control.

RPM Innovations - Directed Energy Deposition (DED), which serves the aerospace industry.

Directed Energy Deposition, or DED, uses a powerful laser to repair or create metal parts for aerospace machinery. It's like using a super-powered flashlight to make aerospace machines work better!

RPM & Associates has one facility which also houses RPM Solutions. RPM Innovations operates in two facilities.

The Story of RPM Innovations. Watch the Legacy Interview below!

-

The Story of RPM Innovations. Watch the Legacy Interview below! -

-

Imagine you have a big box of Lego bricks. Now, each Lego brick is made of a special material called metal. A metallurgical engineer is like a super skilled Lego builder who knows everything about these metal Lego bricks!

Their job is to figure out how to make these metal bricks stronger, lighter, and safer for different things we use every day, like cars, airplanes, and even your bicycle. They study how metals behave, how they can be shaped, melted, and mixed with other stuff to make them better for different purposes.

So, just like how you use your imagination to build cool things with Lego, a metallurgical engineer uses their knowledge to build and improve things using metal!

The Technology of RPM

Robert earned a degree in Metallurgical Engineering. To understand what that means, imagine you have a big puzzle made of different metals like gold, silver, and copper. Metallurgical engineering is like being a super detective for these metals!

People who study metallurgical engineering learn all about these metals: how they're made, how they can be used, and how to make them stronger or change their shape. So, just like you figure out puzzles, metallurgical engineers figure out how to use metals in the best ways possible!

The technology Robert and the RPM team developed can repair metal machine parts or make new replacement parts. In the past this was not possible and if a machine part broke...a new part would need to be purchased. Sometimes the parts were very expensive to buy and sometimes it was impossible to find the part to keep the machine working. The Directed Energy Deposition (DED) technology RPM uses makes it possible to repair or make new machine parts easily.

Learn about the technology RPM developed by watching the following video from their website:

Then explore more on the RPM website by clicking the following links:

Not Knowing How, Did Not Stop RPM!

In early 1991, Robert was asked by an electric company to help solve the severe wear problems with the rotary atomizers (a high-speed spinning disk). This means the metal on a rotary atomizer was getting thin and wearing out. Even though Robert did not know anything about rotary atomizers, he agreed to help. Working with a team, RPM solved the problem and learned to make wear parts for several rotary atomizer systems.

Then in 2001, Robert was asked to help the South Dakota School of Mines and Technology in Rapid City to help them build a laser welding system. Again, Robert did not know how to build this sort of welder; however, working with a team, they produced the first laser system in 2004.

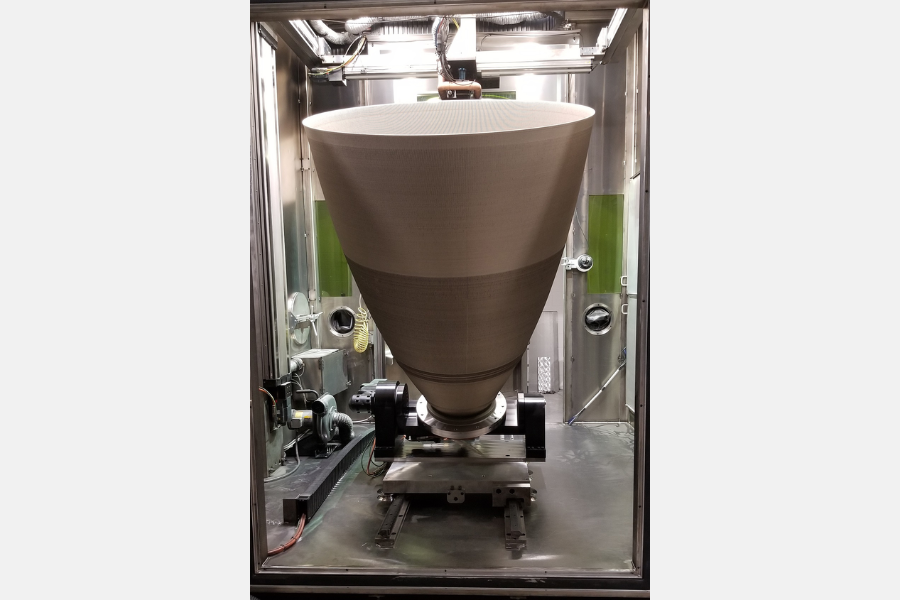

60” diameter and 72” length integral channel wall nozzle that is 65% Scale RS-25 Nozzle fabricated using LP-DED NASA HR-1 Alloy (RPM Innovations / NASA)

To the Moon!

The Directed Energy Deposition (DED) technology (also known as 3-D Printing) RPM uses, may someday produce parts for ROCKET ENGINES!

This is a picture of an integral channel wall nozzle – a rocket engine component - which RPM made for NASA. This, and other rocket engine components RPM is making may one day power a rocket that goes to the moon.

Exploring the Moon with NASA's Commercial Lunar Payload Services

NASA Advances New Alloys and Scale of Metal Additive Manufacturing

Professional Organizations

Mudge is a member of numerous professional organizations, including:

The American Welding Society

ASM International

American Ceramic Society

National Federation of Independent Businessmen

United States Chamber of Commerce

Robert has served on numerous boards supporting youth and those in need.

Philanthropy

Rob and Debbie care about their community and the world and give back by working with several charities.

Reflection:

In the Legacy Interview, Robert Mudge stated:

“You learn every day, every year you get a little older, you go through another year of school, you learn things, you see things, opportunities and opportunities are presented to you and some you embrace and some you, nah – that's not me yet...and that’s how you find yourself through life. The biggest thing is find something you enjoy.”

(Legacy Interview: Robert Mudge, 00:03:58 – 00:04:16)

What does that statement mean to you?

Living in the Black Hills of South Dakota was so important to Robert that he wanted to build his business there.

What was Robert’s motivation for wanting to live in the Black Hills?

At the time this presentation was created (2024), Robert’s company, RPM Innovations, Inc., had been in business for 42 years!

What do you think made the company successful for so long?

Lessons

Robert believes life is about Faith, Family, and Friendship before Fame, Fortune, and Fun. Faith, Family, and Friends—are the foundation, and everything else comes after.

In business, he believes it’s important to keep one’s eye on four things:

Safety First – Nothing matters more than keeping people safe.

Quality – His dad taught him to remember; the best is rarely good enough.

Production – You’ve got to keep things moving and get the job done.

Profit – At the end of the day, you need to make money to keep the doors open.

After learning about Mr. Mudge, discuss the leadership characteristics must Robert possess?

How does knowing about Rob’s life and the businesses he’s built impact your thinking and or inspire you?